Calcium Sulfate Anti-static Activity Floor

Send Inquiry

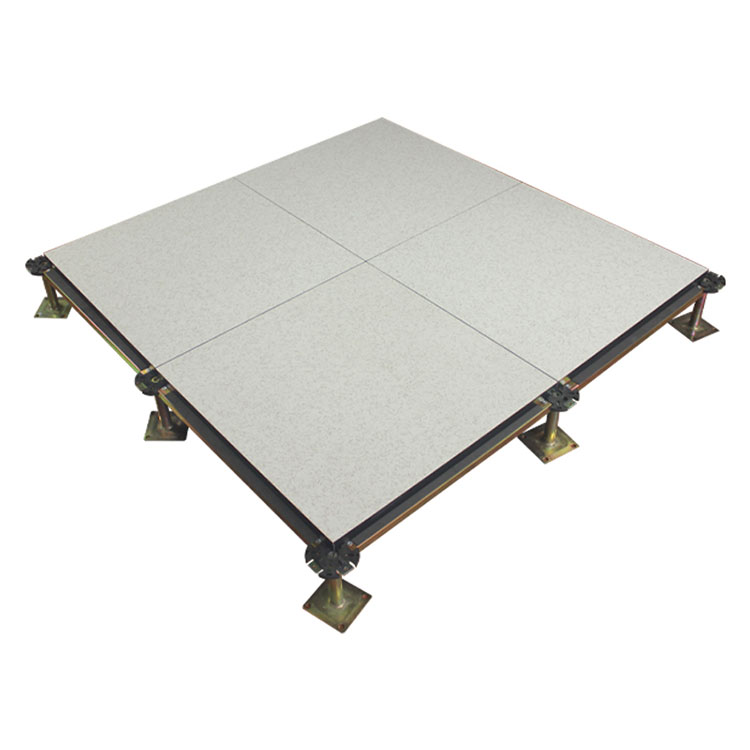

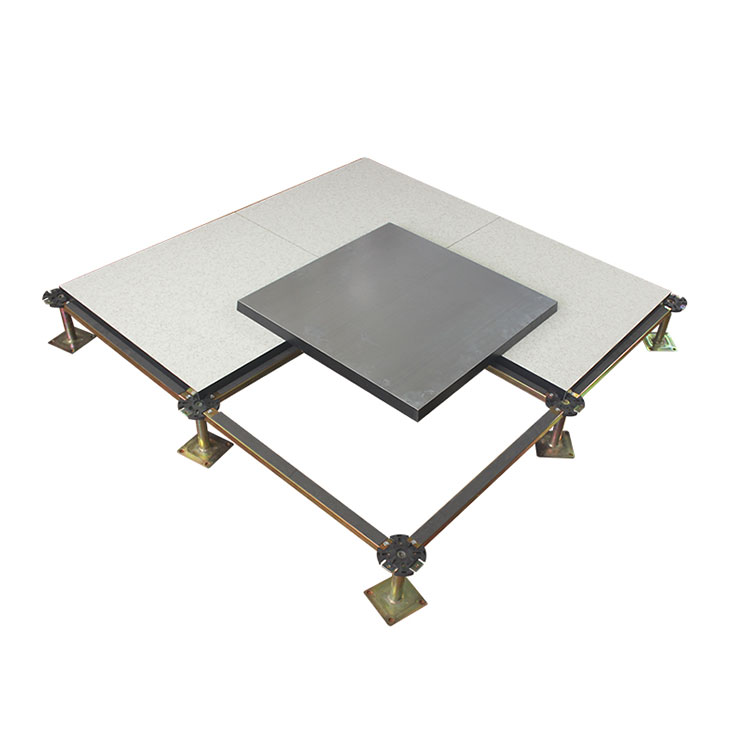

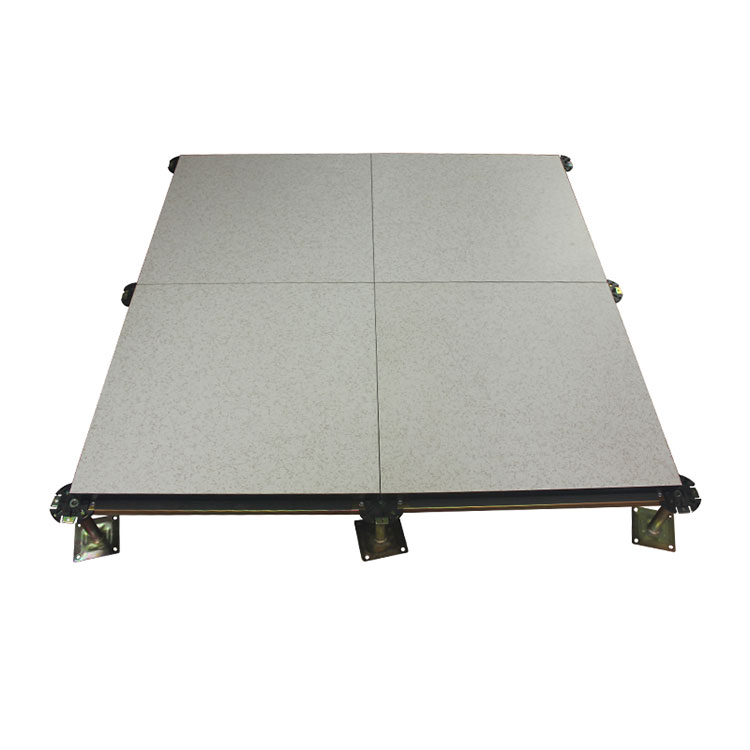

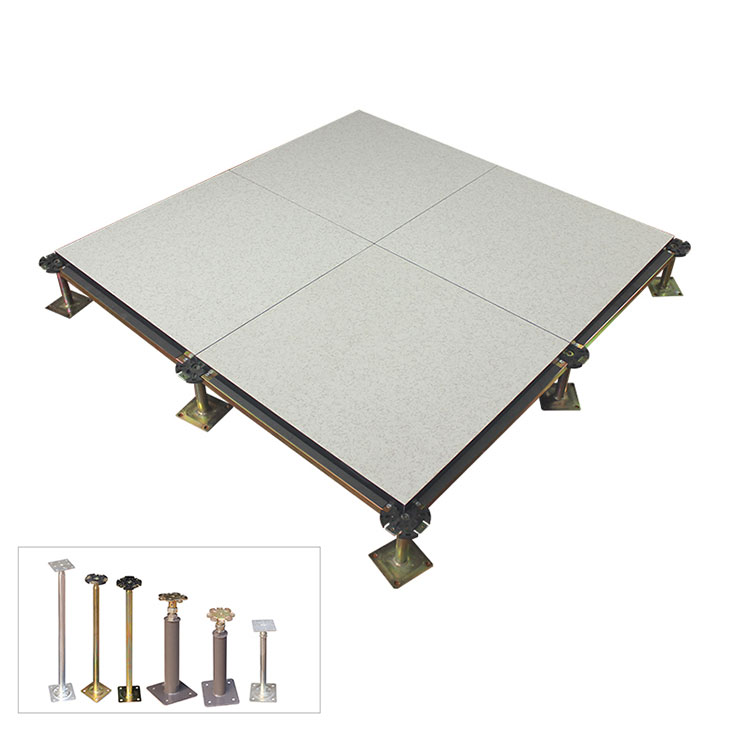

System assembly

The system consists of floor, beams, and supports. The beams and the supports with adjustable height are connected with screws to form a stable lower support system. The floor is inlaid on the grid surrounded by the beams.

Technical parameters

| Model | Specifications (mm) | Concentrated load | Ultimate load | Uniform load | System resistance | |

| N/ | KG | N | (N/m2) | Ω | ||

| OL-1000 | 600×600×32 | ≥4450 | ≥454 | ≥13350 | ≥23000 | 106-109 electrostatic consumption type |

| OL-1250 | 600×600×38 | ≥5560 | ≥567 | ≥16680 | ≥33000 | |

Application Scope

Calcium sulfate anti-static activity floor is suitable for various occasions with high-end anti-static requirements, load-bearing requirements, and paving effect requirements, such as banks, telecommunications rooms, and high-end computer rooms of enterprises and institutions. Mainly used in large computer rooms, communication center rooms, various electrical control rooms, postal and telecommunications hubs, and command centers.

Advantages: large load-bearing capacity and good impact resistance. Flame retardant, heat insulation, sound insulation, etc. Good performance, green and environmentally friendly, no pollution.