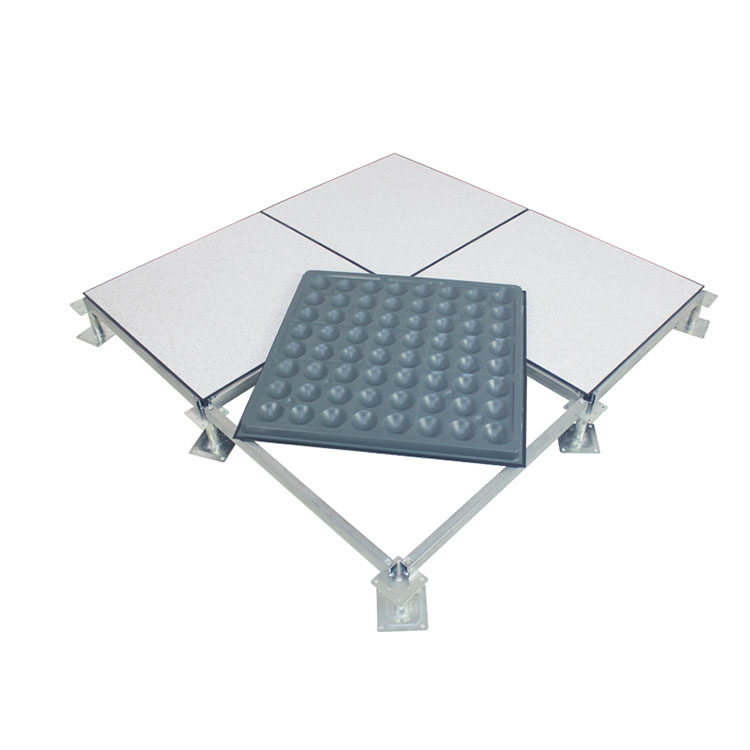

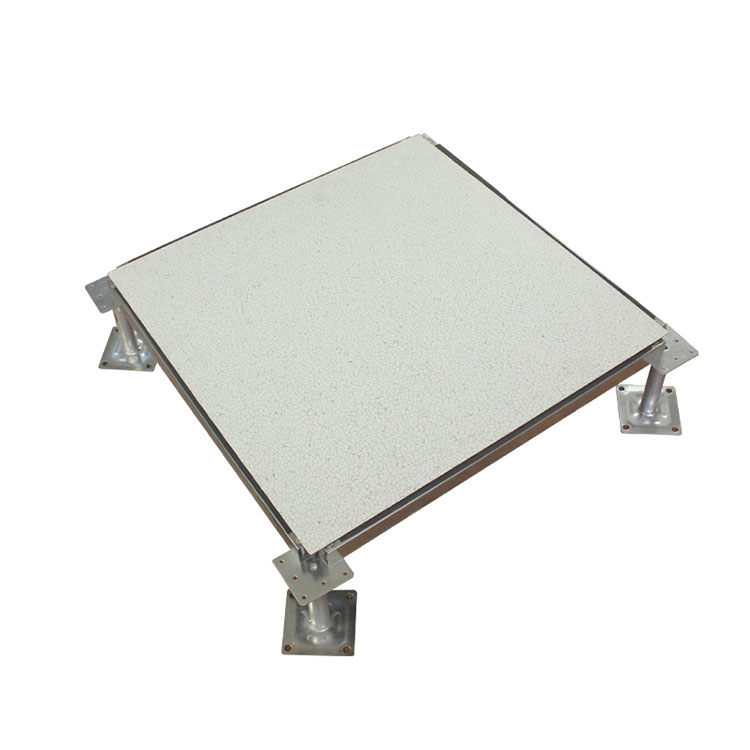

Computer Room All-steel Anti-static Floor

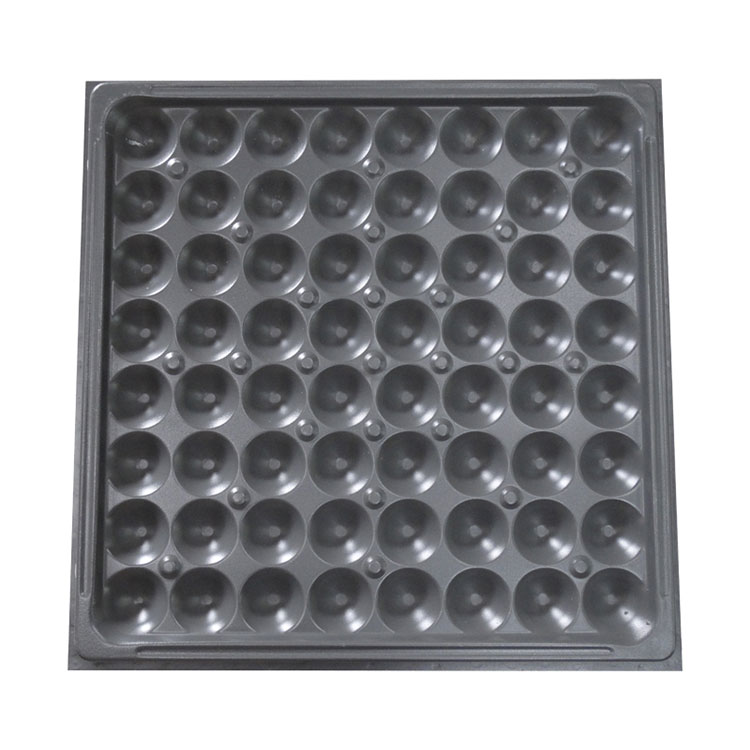

The computer room all-steel anti-static floor is made of alloy cold-rolled steel plate, which has high load-bearing capacity, good elongation, strong corrosion resistance, strong anti-static performance, waterproof, fireproof, anti-corrosion, and good stability in different humidity and environments; the anti-static fit is tight, and we have high requirements for anti-static production of each floor, seamless splicing, and good flatness; the floor is made of honeycomb spherical welding, CNC multi-point welding, and the floor does not rust and has high bearing capacity.

Send Inquiry

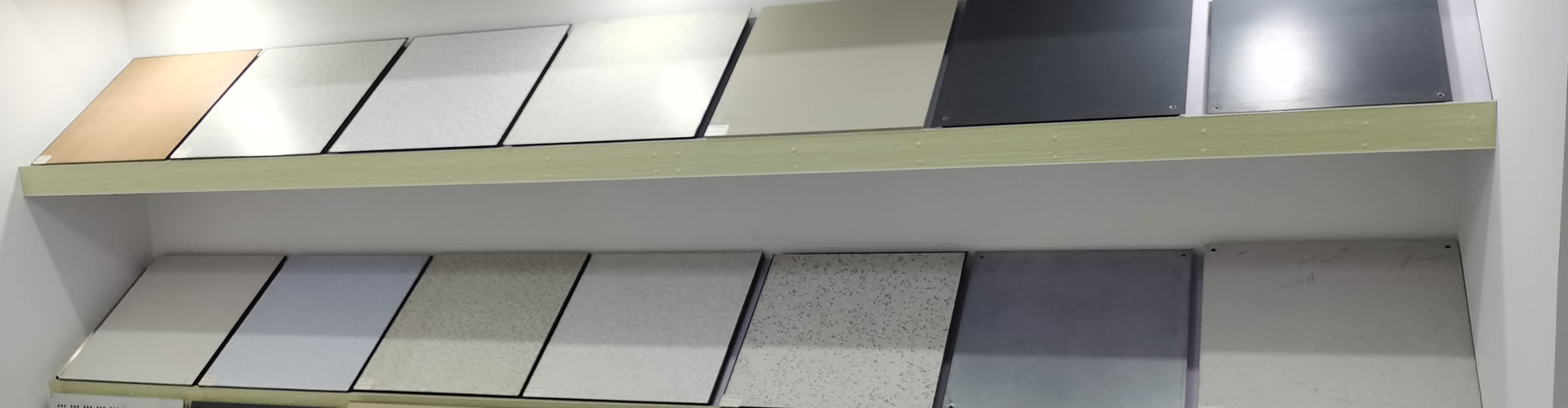

The all-steel anti-static floor is made of high-quality alloy cold-rolled steel plate (Baosteel steel), which is spot welded after stretching. The surface is electrostatically sprayed after phosphating, the inner cavity is filled with standard pure cement, and the upper surface is pasted with high wear-resistant and fire-resistant high-pressure layer (HPL) or PVC board (bare board without veneer), and the surrounding edges are straight or folded.

The computer room all-steel anti-static floor is poured with cement in a die-cast metal shell. The conductivity of the metal shell is very high and the anti-static performance is outstanding. In addition, the scientific mechanical structure of the all-steel floor makes its bearing capacity 30% higher than other floors of the same specifications, with thickened steel plates and super strong bearing. Paste thick wear-resistant HPL veneer, high wear resistance, thick balance paper treatment, completely solve the problem of breakage. There is no black edge around, the paving effect is beautiful and generous, it is a high-end product among all-steel floors.

Product Features

Made of steel, large bearing capacity, strong impact resistance;

Filled with special foam cement inside, comfortable and stable stepping, good sound absorption, heat insulation and fireproof performance;

All raw materials have high-quality antistatic properties, making the floor system performance stable and reliable;

The decorative surface of the all-steel floor is decorated with HPL (Italian Abet series) decorative surface with static dissipation;

The mechanical properties of the floor belong to the ultra-light series;

The floor is decorated with black static conductive strips around, which further enhances the antistatic function of the system and makes the appearance more beautiful;

The decorative surface is better in terms of wear resistance and fireproof performance.

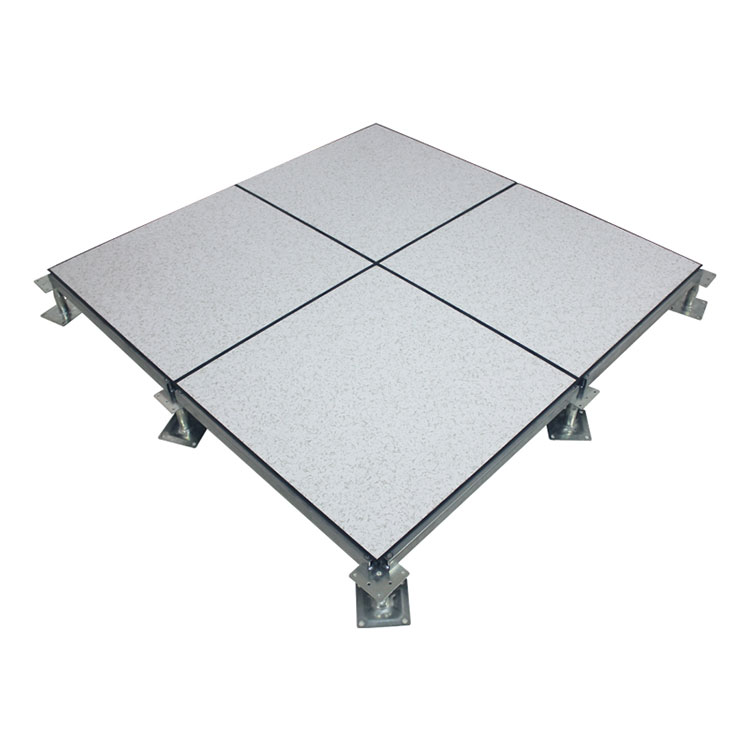

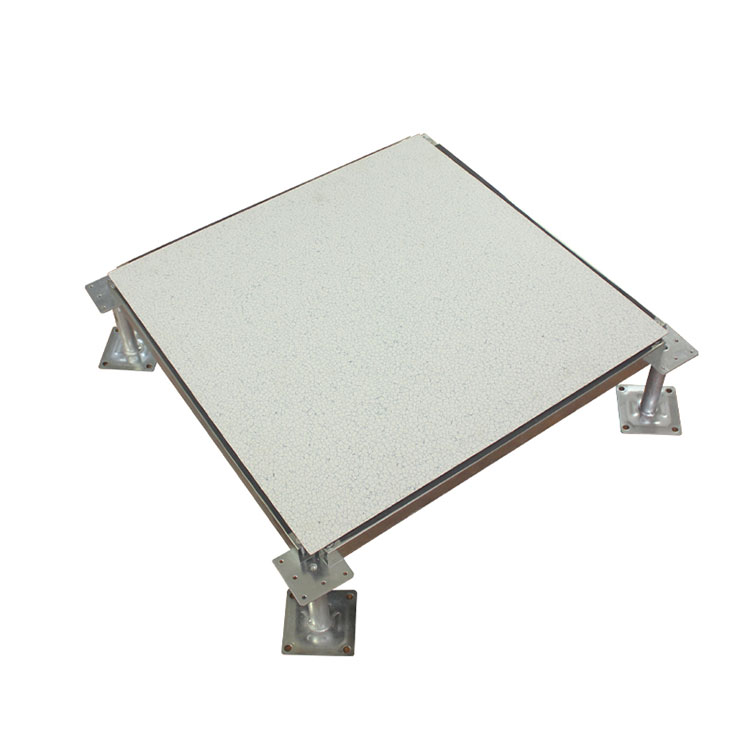

System Assembly

The system consists of floors, beams, and supports. The beams and the supports with adjustable heights are connected with screws to form a stable lower support system, and the floor is inlaid in the grid formed by the beams.

Technical parameters (standards met: GB/T36340-2018 and SJ/T10796-2017)

| Model | specification(mm) | Concentrated load on the board | Shock loads | Ultimate load | Evenly distributed loads | Fire performance | System resistance | |

| N | KG | LB/KG | N | (N/m2) | Ω | |||

| FS700 | 600×600×35 | ≥2940 | ≥300 | 100/45 | ≥8850 | ≥14710 |

ASTM E84-01:Flame spread:0 Smoke Density:0 |

Conductive type:10⁴-10⁶ Electrostatic consumption type:10⁶-10⁹ |

| FS800 | 600×600×35 | ≥3560 | ≥363 | 100/45 | ≥11250 | ≥17780 | ||

| FS1000 | 600×600×35 | ≥4450 | ≥454 | 150/68 | ≥14500 | ≥22220 | ||

| FS1250 | 600×600×35 | ≥5560 | ≥567 | 150/68 | ≥18360 | ≥27780 | ||

| FS1500 | 600×600×35 | ≥6680 | ≥680 | 175/68 | ≥22170 | ≥33340 | ||

| FS2000 | 600×600×35 | ≥8890 | ≥907 | 175/68 | ≥29420 | ≥44450 | ||

Application

The floor is widely used in computer rooms, satellite ground station rooms, radio control rooms, TV transmitter control rooms, microwave communication station rooms, program-controlled switch rooms, clean workshops, electronic instrument factory assembly workshops, confidential optical instrument manufacturing workshops, hospitals, schools and other places with anti-static requirements.