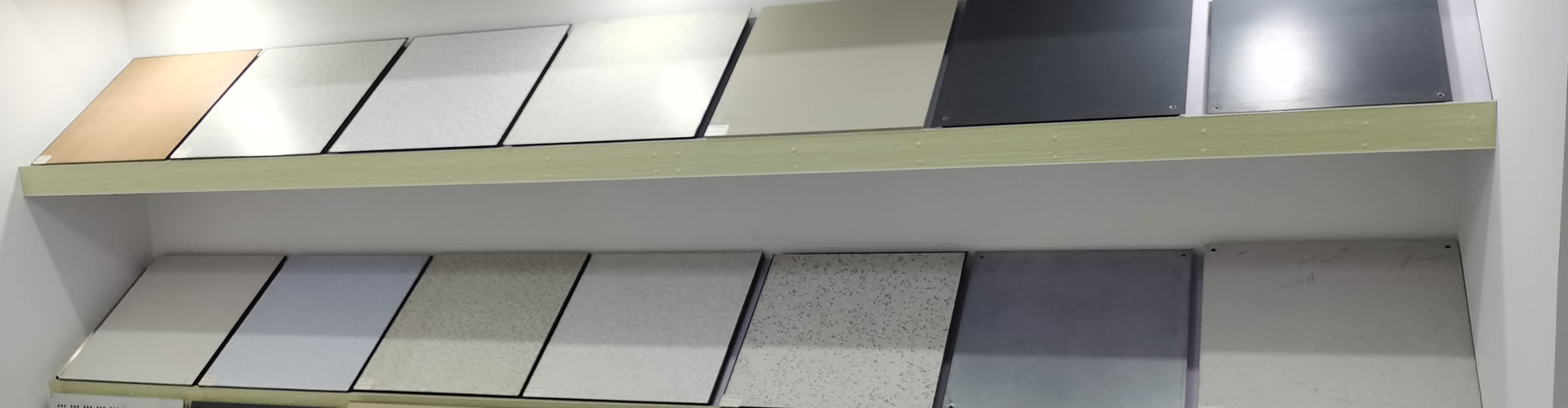

Inorganic OA Cement Floor

Send Inquiry

| Model | Specifications (mm) | Concentrated load (deflection ≤ 2mm) | Ultimate load | Uniform load | Fire performance | System resistance | |

| N | KG | N | (N/m2) | Ω | |||

| FS660 | 500×500×25 | ≥2940 | ≥300 | ≥8850 | ≥14710 |

ASTM E84-01:Flame spread:0 Smoke Density:0 |

|

| FS800 | 500×500×25 | ≥3560 | ≥363 | ≥11250 | ≥17780 | ||

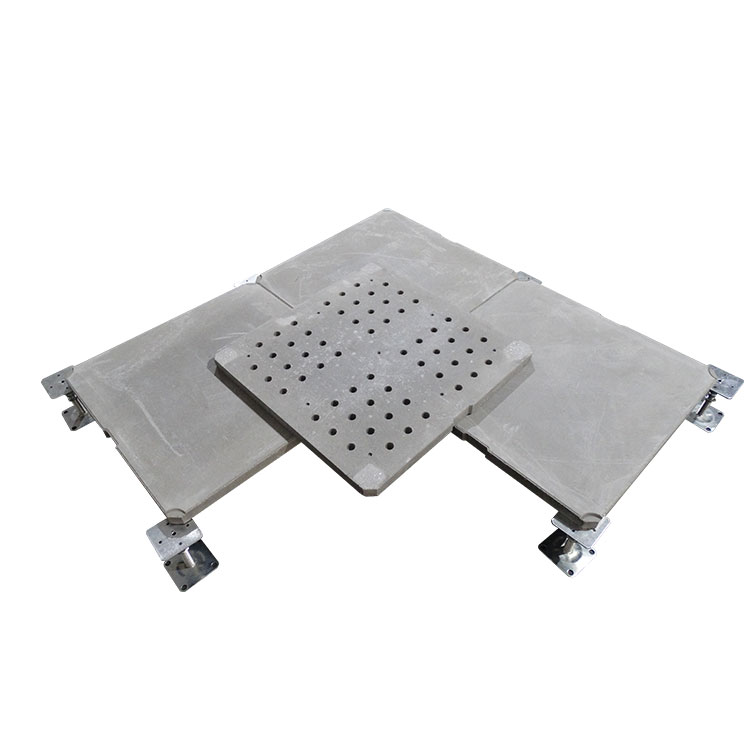

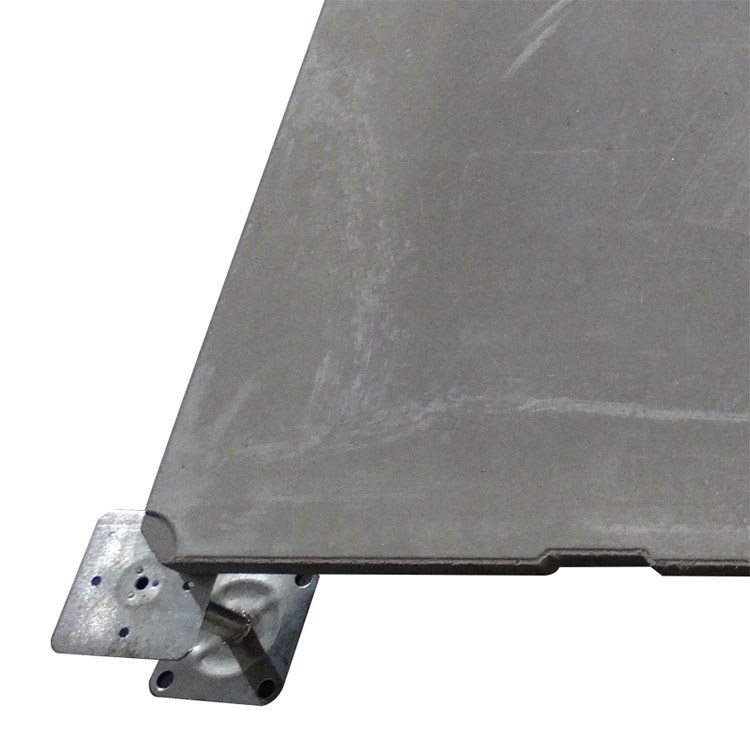

Product structure

Inorganic OA Cement Floor is an environmentally friendly floor made of silicate, inorganic fiber, mineral fiber, quartz sand and other materials through high pressure one-time molding. Each floor has its own threading hole. The floor is supported by a galvanized base at the four corners without a beam system. Each floor has a 90-degree arc at the four corners. After the four floors are combined, a circle is formed, and there is an aluminum nut to fix the angle. The aluminum head is equipped with a circular buffer positioning rubber pad to prevent the noise caused by the vibration of the floor after being stressed.

Product Features

Fireproof, waterproof, large bearing capacity, long service life.

Inorganic silicate has a very good heat insulation effect and is a permanent non-combustible solid. When a 600-degree Celsius flame intensity is transmitted from one side of the floor to the other side, it takes 1 hour, which is enough time to escape or rescue property. Inorganic silicate is insoluble in water. If there is a leak, the floor will not affect the quality of the floor even if it is completely soaked in water. It can be tried out. The main material of the inorganic network floor is similar to the main material of the building, so its service life is the same as that of the building.

Product performance

Each board of the inorganic network floor has its own outlet hole. If the amount of outlet wires under the workstation is not much, there is no need to open a hole on the floor surface, and it can be directly led out from the self-contained outlet hole. If the amount of outlet wires is large, it can be replaced with a one-time molded outlet plate, without cutting the floor after the floor is delivered, causing environmental pollution. After installation, the inorganic network floor has high flatness and no soft feeling. Its surface can be laid with laminate flooring, PVC, square carpet, etc., while ordinary steel network floor can only be laid with square floor. The surface and interior of the inorganic network floor use the same material, and are not afraid of scratches and grinding by hard objects or metal objects. Once damaged, they can be repaired at any time, so the floor is suitable for cross-construction. The cutting edge of the inorganic network floor will not rust or corrode during paving. The floor is suitable for use in marine environments and rooms with radiators.

Place of use

Applicable to building prefabricated houses, 5A-level intelligent buildings, 5A-level office buildings, smart offices, control rooms, computer rooms, teaching buildings, dust-proof and waterproof places, and places that require overhead and network integrated wiring. It is more suitable for the ground renovation of the integrated wiring of old office buildings, and is generally used in conjunction with anti-static square carpets.

Cement board with built-in steel bars

Bracket