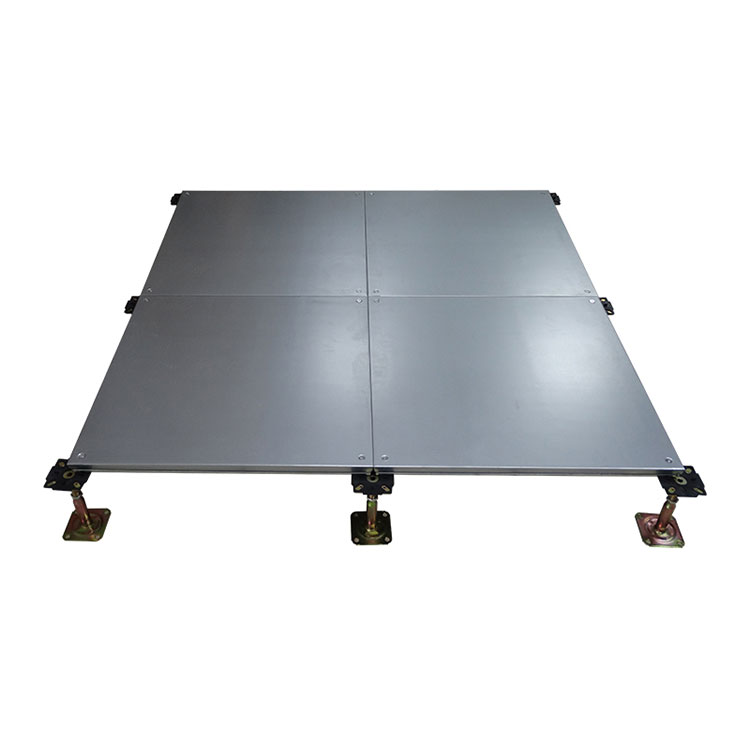

Network Flooring and Office Flooring Floor

Send Inquiry

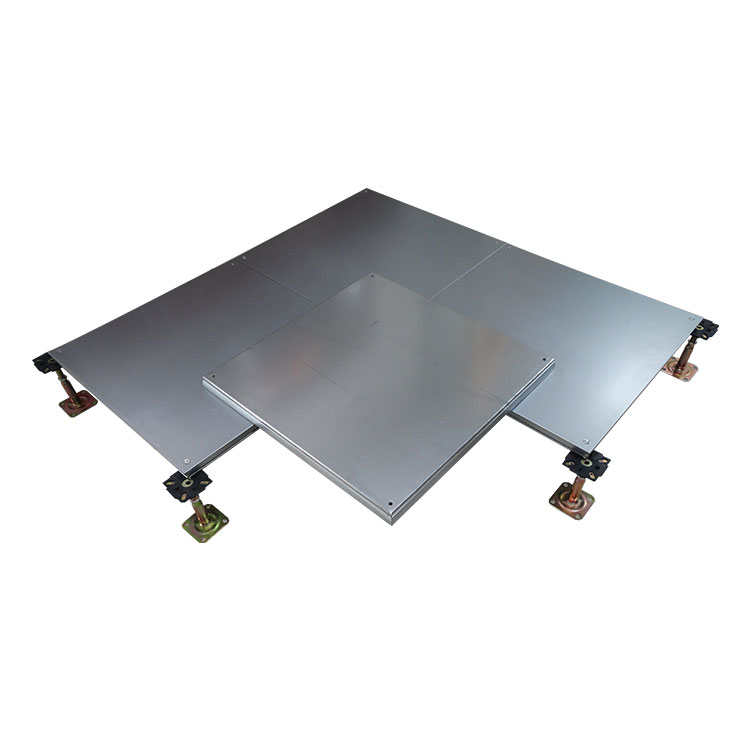

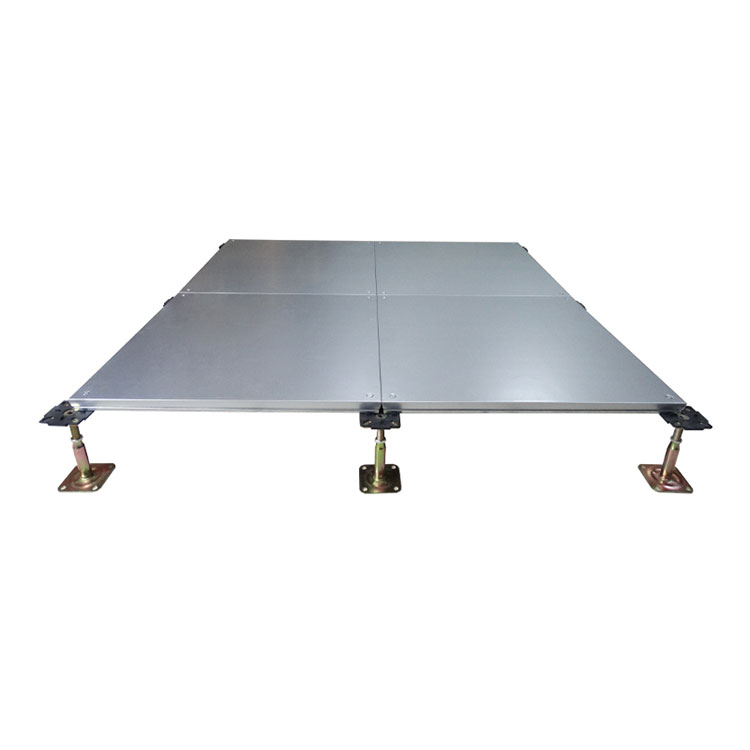

System Assembly

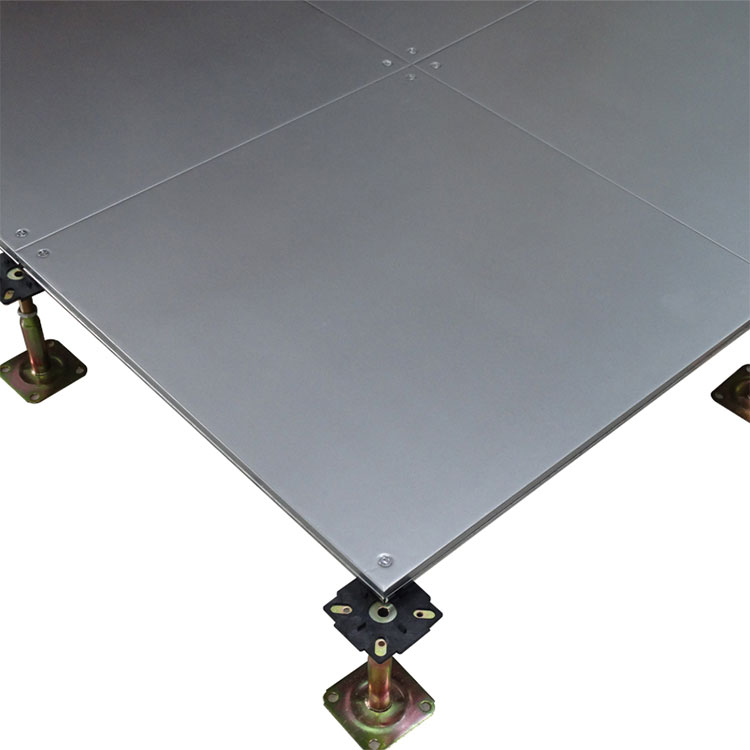

The bracket is molded, with a plastic pad on the upper support, and the minimum finished surface height is 50mm. It can adopt a beam-around support structure or a bracket-four-corner support structure.

Technical parameters

| Model | Specifications (mm) | Concentrated load | Impact load | Ultimate load | Uniform load | Rolling load | |

| N | KG | N | N | (N/m2) | N | ||

| FS800 | 600×600×30 | ≥3560 | ≥363 | 670 | ≥10680 | ≥16000 | ≥3560 |

Features

1. Base material purity >85%, has reached international standards.

2. Hexagonal galvanized steel with good sealing performance and waterproof.

3. High dimensional accuracy, super strong load-bearing and pressure-resistant.

4. The height of the bracket can be adjusted, the assembly is flexible, the wiring volume is large, and the interchangeability is good.

5. Various films can be laid on the surface, which is beautiful and generous.

6. High reuse rate, easy disassembly and assembly, cost saving, and long service life.

Structure

1. High-quality calcium sulfate base (purity> 85%), with or without corner lock holes at the four corners, the surface can be paved with carpet, PVC or other materials.

2. The bracket is molded, with a plastic pad on the upper support, and the finished surface height is 70mm-1500mm. The beam can be supported all around or the bracket can be supported at the four corners.